VSM HT Submersible Motors (6”-7”-8”-10”)

Features

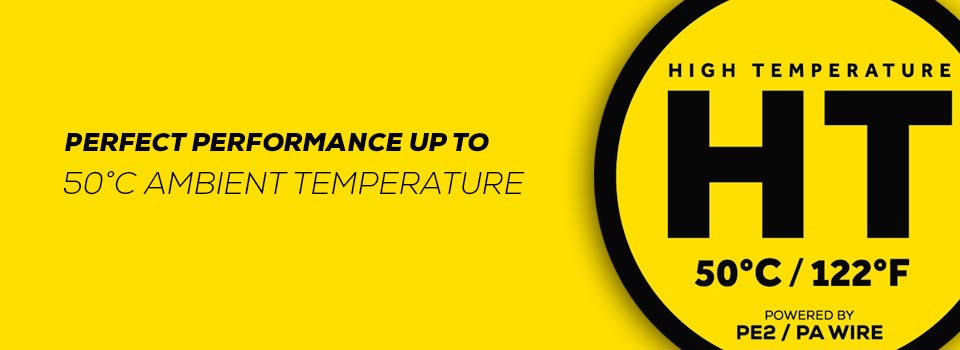

- PE2/PA insulated top quality winding wire

- 20% more power than normal motor

- Excellent performance at well water of 50 °C

- High resistance against voltage fluctuations

- Longer lifespan

General Features

- Rewindable VSM motors up to 220 kW

- High efficiency provides operation cost savings

- Water coolant system

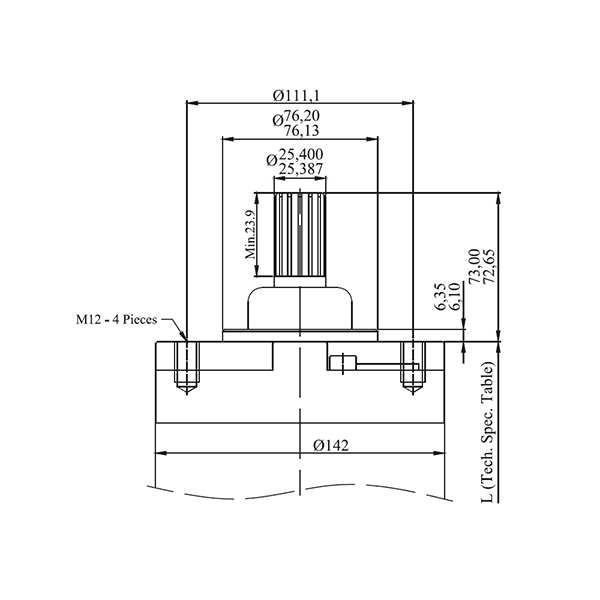

- Flange with NEMA standards

- Stainless steel shaft

- Optional high corrosion resistive materials (AISI 304 – AISI 316 – Duplex – Bronze)

- Max. ambient water temperature 70°C optional

- Standard voltage 380/460V – 50/60Hz (Allowable voltage tolerance ±%10. )

- Variable operation revolutions by frequency convertor (over 30Hz)

- Availability to be operated by Soft-Starter

- CW & CCW direction of rotation.

- Rewindable, PVC, PP & PE2+PA winding wire. Our rewindable motors provides long service life.

- Our motors can be operated horizontally if motors will be installed in open body of water (i.e pool )

Excellent performance at well water of 50 °C. High resistance against valtage surges. 20% more power than normal motors.

Heavy duty bearings provides the option to revolve both sides, has the capacity to carry high thrust load.

Although mechanical seal is optionally used by other companies, it is always used by Vansan as a standard, to prevent sand and other particles to get in motors to provide long bearing life.

Chrome-plated and precisely machined bearing collets which are located in the radial bearings operating area, have great importance for bearing the rotor.

Pressure balancing checkvalves controls the pressure changes inside the motor. When the pressure increases, it throw water out of the motor. When the pressure drops, it filtrates the water inside well and gets it inside the motor by the help of this checkvalves to balance the pressure inside. That’s why pressure differences inside motor never causes membrane under motor to blow up.

Gallery

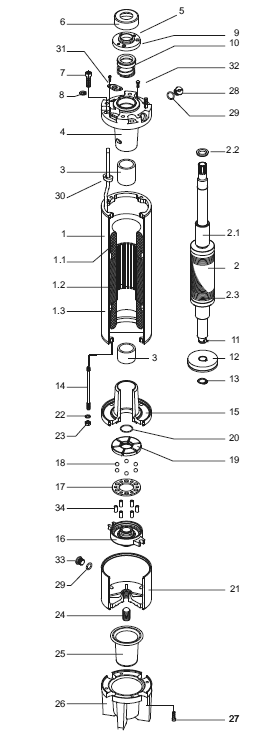

| Nr | Part Name | Material |

|---|---|---|

| 1 | Stator | – |

| 1.1 | Winding wire | PVC – P.P |

| 1.2 | Stator package | M350 / Magnetic Seal |

| 1.3 | Stator shell | AISI 304 |

| 2 | Rotor | – |

| 2.1 | Shaft sleeve | St 37 (Coated CrNi) |

| 2.2 | Balance ring | St 37 |

| 2.3 | Copper ring | Cu |

| 3 | Radial bearing | Carbon |

| 4 | Upper bearing body | GG20-22 |

| 5 | Bushing | Bronze |

| 6 | Slinger (sand guard) | NBR_EPDM |

| 7 | Hexagon socket cap screws | Inox |

| 8 | Copper ring | Cu |

| 9 | Cover seal | AISI 420 |

| 10 | Mechanical seal | Seramic Carbon |

| 11 | Axial thrust bearing key | AISI 420 |

| 12 | Axial thrust bearing | Carbon With Antimony |

| 13 | Retaining ring | St 37 |

| 14 | Tie rod | Inox |

| 15 | Lower bearing body | GG20-22 |

| 16 | Thrust bearing support | GG20-22 |

| 17 | Ball holder | St 37 ( Coated Cr+3) |

| 18 | Thrust bearing ball | Inox |

| 19 | Tilting pads | AISI 420 |

| 20 | O-ring | NBR 70 |

| 21 | Thrust bearing body | GG20 |

| 22 | Copper ring | Cu |

| 23 | Nut | Inox |

| 24 | Screw (thrust bearing base) | Inox |

| 25 | Membrane | NBR-EPDM |

| 26 | Membrane body | GG22 |

| 27 | Hexagon socket cap screws | Inox |

| 28 | Check-valve | Bronze |

| 29 | O-ring | NBR 70 |

| 30 | Cable seal | NBR |

| 31 | Seal cover | AISI 304 |

| 32 | Nut | Inox |

| 33 | Plush (r 3/8″) | Bronze |

| 34 | Ball holder pins | Inox |

General Features

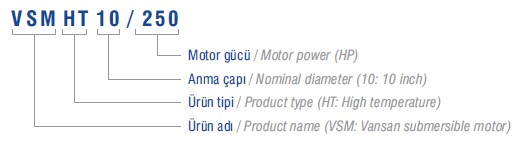

Product Code System