General

VIP – Vertical Multistage In-line Pumps

Technical Features

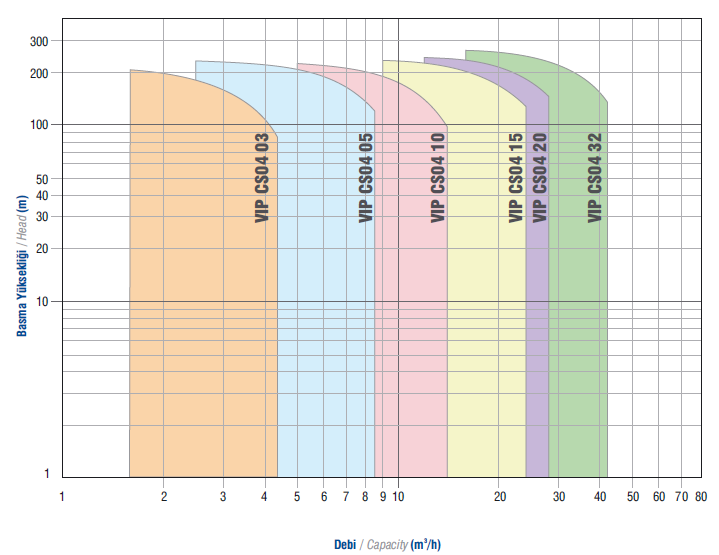

- Max. capacity 200m³/h

- Max. head 305 m

- Max. power 30 kW

- Between -20º and 120º temperature range

- Max. 25 bar operating pressure

- Stainless Steel options

- Pump-integrated liquid sensor

- John Crane mechanical seal

Features

All Vansan-VIP Pumps are produced with Si-C cartridge type mechanical seal provides the longlife and maintanence free operation.

The removable coupling design supplies easy replacement operation for the motor without dismautling the pump from the pipeline.

All impellers and difusers are made from AISI304 Stainless Steel. As an option the net pants of the top & bottom brackets can also made from AISI304.

Additional Features

In-Line Pump With Frequency Inverters

The use of frequency inverters increasing the life time of the booster system and acc. to the system the arrangement of the speed will same energy.

– Superior energy saving.

– Extremely silent operation performance

– Much longer working life

– Superior energy saving.

– Extremely silent operation performance

– Much longer working life

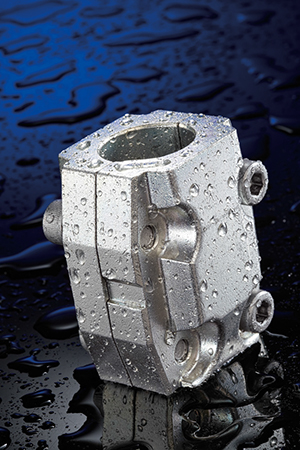

Stainless İnlet&Outlet

It is a must to use stainless steel components to pump an agressive water or in the application of drinking water pumping..

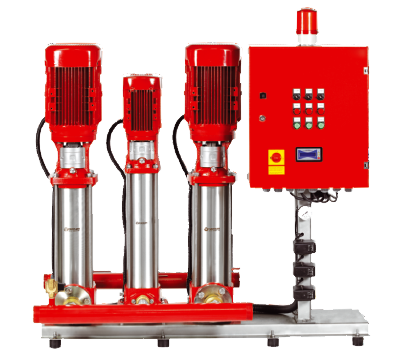

In-Line Fire Fighting Pumps

” Vansan Vertical Multistage In-Line Fire Fighting Pumps”, certified by NFPA, are used for fire fighting systems with capacity range “20-100 m3/h” for industrial plants and residential buildings applications in general.

Product

General Performance

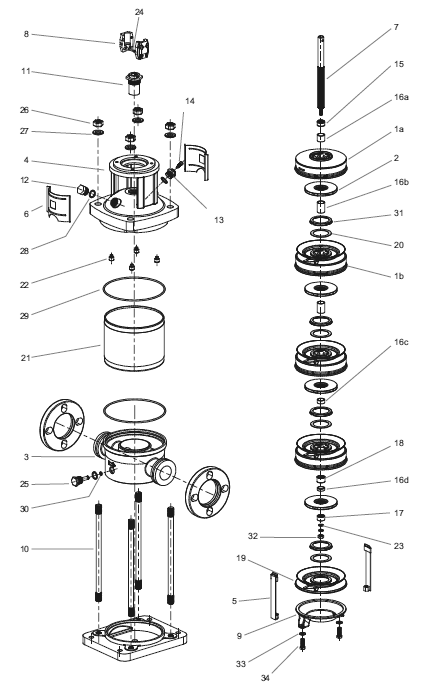

Parts

| NO | Part Name | Material |

|---|---|---|

| 1a | Chamber | Stainless Steel (AISI 304) |

| 1b | Chamber | Stainless Steel (AISI 304) |

| 2 | Impeller | Stainless Steel (AISI 304) |

| 3 | Suction Case | Stainless Steel (AISI 304) |

| 4 | Pump Head | Stainl.(GG25), Steel (AISI304) |

| 5 | Strap | Stainless Steel (AISI304) |

| 6 | Coupling Guard | Stainless Steel (AISI304) |

| 7 | Shaft | Stainless Steel (AISI 420) |

| 8 | Coupling | Stainless Steel (AISI304) |

| 9 | Discharge | Stainless Steel (AISI304) |

| 10 | Staybolts | Stainless Steel (AISI 420) |

| 11 | Shaft Seal | – |

| 12 | Plug | Stainless Steel (AISI 303) |

| 13-14 | Vent Plug | Stainless Steel (AISI 303) |

| 15 | Stop Spacer | Stainless Steel (AISI 316) |

| 16 | Spacing Pipe | Stainless Steel (AISI 304) |

| 17 | Stop Nut | Stainless Steel (AISI 316) |

| 18 | Bearing Ring | Silicon Carbide (SiC) |

| 19 | Centrilizer Suction Sheet | Stainless Steel (AISI 304) |

| 20 | Neck Ring | Teflon / Teflon |

| 21 | Outer Sleeve | Stainless Steel (AISI 304) |

| 22 | Stop Spacer | Rubber |

| 23 | Lock Washer Set For Shaft | Stainless Steel (AISI 316) |

| 24 | Shaft Pin | Stainless Steel (AISI 304) |

| 25 | Drain Plug | Stainless Steel (AISI 303) |

| 26 | Bolt | Stainless Steel (AISI 304) |

| 27 | Washer | Stainless Steel (AISI 304) |

| 28 | O-ring | Rubber |

| 29 | O-ring | Rubber |

| 30 | O-ring | Rubber |

| 31 | Neck Ring Retainer | Stainless Steel (AISI 304) |

| 32 | Lock Nut For Shaft | Stainless Steel (AISI 304) |

| 33 | Washer | Stainless Steel (AISI 304) |

| 34 | Bolt | Stainless Steel (AISI 1050) |

Others

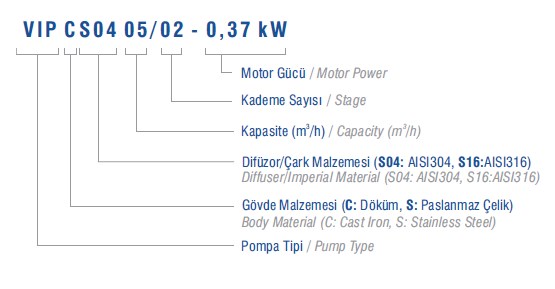

Product Code System