Axial Flow Vertical Turbine Pumps

Production Up To 30.000m³/h

Axial Flow Pumps are ideal for the low pressure & high capacity application. Vansan can produce in between capacities 900 m³/h – 30.000 m³/h up to 8 m pressures.

Technical Features

- %93 performance

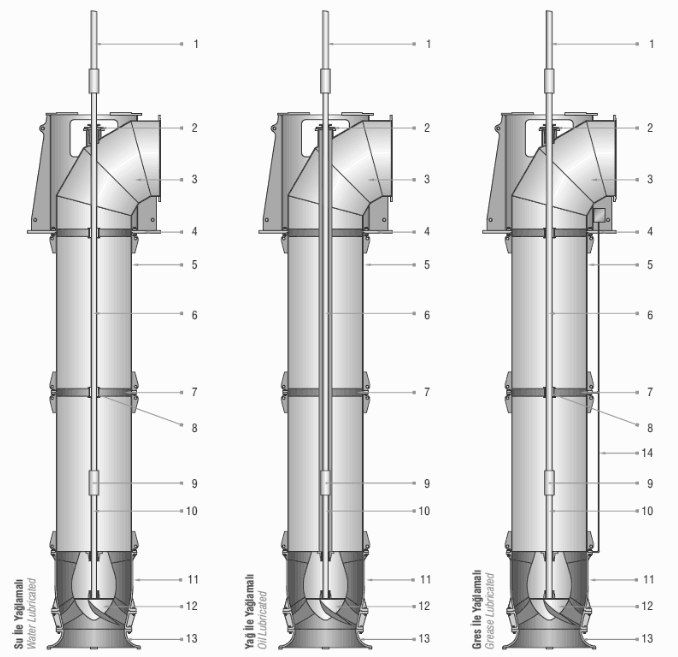

- Water, oil, grease lubrication options

- Specific design and material option

Application

- Industrial

- Flood Control

- Cooling Towers

- Land Drainage

- Irrigation

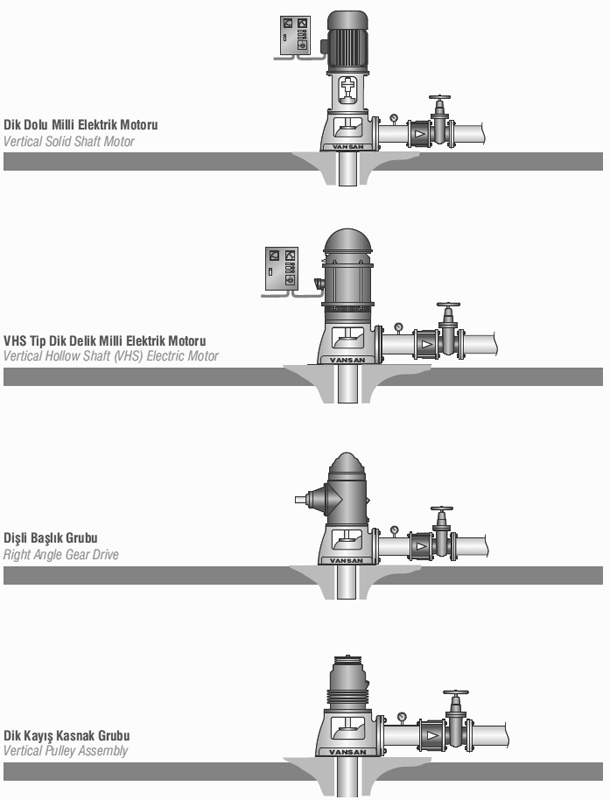

Driver

The propeller pump is driven by solid shaft motors or vertical hollow shaft motors

Thrust Assembly

Elbows are available in both the above base or below base type. The discharge opening can be either plain end or flanged , depending upon requirements.

Suction Case

Vansan Axial Flow Pumps’ Suction Cases are designed to have water entry parallel to pump shaft. The reason is to provide maximum efficiency and minimum friction losses. Suction Filters are designed to prevent unwanted parts to get inside the pump

Discharge Head

Elbows are available in both the above base or below base type. The discharge opening can be either plain end or flanged , depending upon requirements.

Column Pipe and Column Shaft

Manufactured from stainless steel material, the pump shafts are dimensioned to operate without vibration and without any problems. The column pipe is manufactured with flange to correspond to the desired pump length. Lubrication of the column shafts can be done either with the fluid it compresses or with the oil to be placed externally in the shaft casing.

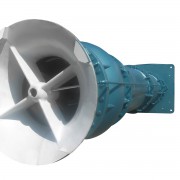

Impeller

Heavy dust cast aluminium bronze ( stainless steel or ductile cast iron available ) are balanced to assure vibration free operation and hard finished for maximum performance . The propeller secured to the shaft by a simple key , split thrust ring and retainer, assures positive drive and adequate locking. The axial flow propeller has a single inlet , available in numerous pitches to allow the flow to enter axially and discharge nearly axially for maximum capacity discharge.

Diffuser

Axial pumps are generally produced in one stage as they can be produced in two stages. The bearings are specially designed to extend the life of the diffuser and the shaft.

Stuffing Box

Soft seal is used and there are simple and easy maintenance.

Gallery

| Part Name | Material | |

| 1 | Head Shaft | AISI 420 |

| 2 | Stuffing Box | ASTM A48 |

| 3 | Discharge Elbow | ASTM A48 / Fabricated Steel |

| 4 | Base Plate | ASTM A48 / Fabricated Steel |

| 5 | Column Pipe | Fabricated Steel |

| 6 | Line Shaft | AISI 420 / AISI 316 |

| 7 | Bearing Retainer | ASTM A48 |

| 8 | Bearing | Rubber SAE 63 |

| 9 | Shaft Coupling | AISI 420 / AISI 316 |

| 10 | Pump Shaft | AISI 420 / AISI 316 |

| 11 | Diffuser | ASTM A48 |

| 12 | Impeller | ASTM A48 / SAE 63 / AISI 316 |

| 13 | Suction Bell | ASTM A48 |

| 14 | Grease Tube | AISI 316 |

TURBINE PUMPS DRIVE VARIETIES