Turkey and Europes most Important Manufacturer of Geothermal Pumps: VANSAN

First Geothermal Line Shaft Pump operating at 500 m depth

“Maren Aydin – Germencik Geothermal Pump Project” again from Vansan

Vansan Pumps is the first Geothermal Down Hole Pump manufacturer in Turkey. Vansan Geothermal Pumps are successfully used up to 200 º C geothermal fluid temperatures since 1984. Vansan can be produced pumps up to 700 m installation depth. In many district heating systems and green house heating systems. Our Geothermal Pump designed for “Maren Aydın-Germencik

Geothermal Pump Project” which was taken into operation in March 2018 has a depth of 500 meters. Vansan is still one of the most important Geothermal Pump Producer in Europe. Vansan is involved in the project from the feasibility of the project to after sales service. Vansan continues to be one of the few companies in the world with achieving to produce these pumps.

Gallery

| Client | Project | Place | Pcs | Q (m³/h) | H(m) | Power | Date |

| Maren Energy | Germencik Geothermal Power Plant | Aydin | 2 | 450 | 210 m | 250 kW | 2018 |

| Greeneco Energy | Sarayköy Geothermal Power Plant | Denizli | 3 | 500 | 204 m | 400 kW | 2018 |

| Maspo Energy | Alasehir Geothermal Power Plant | Manisa | 3 | 290 | 70 m | 90 kW | 2017 |

| Maspo Energy | Alasehir Geothermal Power Plant | Manisa | 3 | 290 | 370 m | 500 kW | 2017 |

| Guris Holding | Efe6 Geothermal Power Plant | Aydin | 4 | 680 | 330 m | 850 kW | 2017 |

| Enerjeo Energy | Alasehir Geothermal Power Plant | Manisa | 3 | 1250 | 150 m | 800 kW | 2017 |

| Sis Energy | Alasehir Geothermal Power Plant | Manisa | 12 | 220 | 315 m | 250 kW | 2016 |

| Sis Energy | Alasehir Geothermal Power Plant | Manisa | 2 | 300 | 90 m | 132 kW | 2016 |

| Sis Energy | Alasehir Geothermal Power Plant | Manisa | 4 | 400 | 470 m | 1000 kW | 2016 |

| Maren Energy | Mehmethan Geothermal Power Plant | Aydin | 3 | 750 | 100 m | 355 kW | 2016 |

| Maren Energy | Ken3 Geothermal Power Plant | Aydin | 6 | 350 | 350 m | 500 kW | 2016 |

| Karizma Energy | Germencik Geothermal Power Plant | Aydin | 5 | 750 | 200 m | 710 kW | 2016 |

| Greeneco Energy | Sarayköy Geothermal Power Plant | Denizli | 2 | 280 | 220 m | 315 kW | 2016 |

| Sis Energy | Alasehir Geothermal Power Plant | Manisa | 4 | 350 | 270 m | 355 kW | 2015 |

| Enerjeo Energy | Irem Geothermal Power Plant | Manisa | 1 | 450 | 210 m | 355 kW | 2015 |

| Guris Holding | Efe4 Geothermal Power Plant | Aydin | 2 | 450 | 67 m | 132 kW | 2015 |

| Enerjeo Energy | Alasehir Geothermal Power Plant | Manisa | 2 | 475 | 20 m | 37 kW | 2015 |

| Enerjeo Energy | Alasehir Geothermal Power Plant | Manisa | 12 | 250 | 20 m | 22 kW | 2015 |

| Enerjeo Energy | Alasehir Geothermal Power Plant | Manisa | 7 | 525 | 300 m | 630 kW | 2015 |

| Maren Energy | Ken1 Geothermal Power Plant | Aydin | 5 | 375 | 270 m | 450 kW | 2014 |

| Guris Holding | Efe2 Geothermal Power Plant | Aydin | 4 | 490 | 320 m | 710 kW | 2014 |

| Guris Holding | Efe3 Geothermal Power Plant | Aydin | 2 | 450 | 80 m | 160 kW | 2014 |

| Guris Holding | Efe2 Geothermal Power Plant | Aydin | 2 | 300 | 136 m | 160 kW | 2014 |

| celikler Holding | Sarayköy Geothermal Power Plant | Denizli | 2 | 500 | 120 m | 250 kW | 2014 |

| Bereket Energy | Sarayköy Geothermal Power Plant | Denizli | 3 | 350 | 320 m | 450 kW | 2014 |

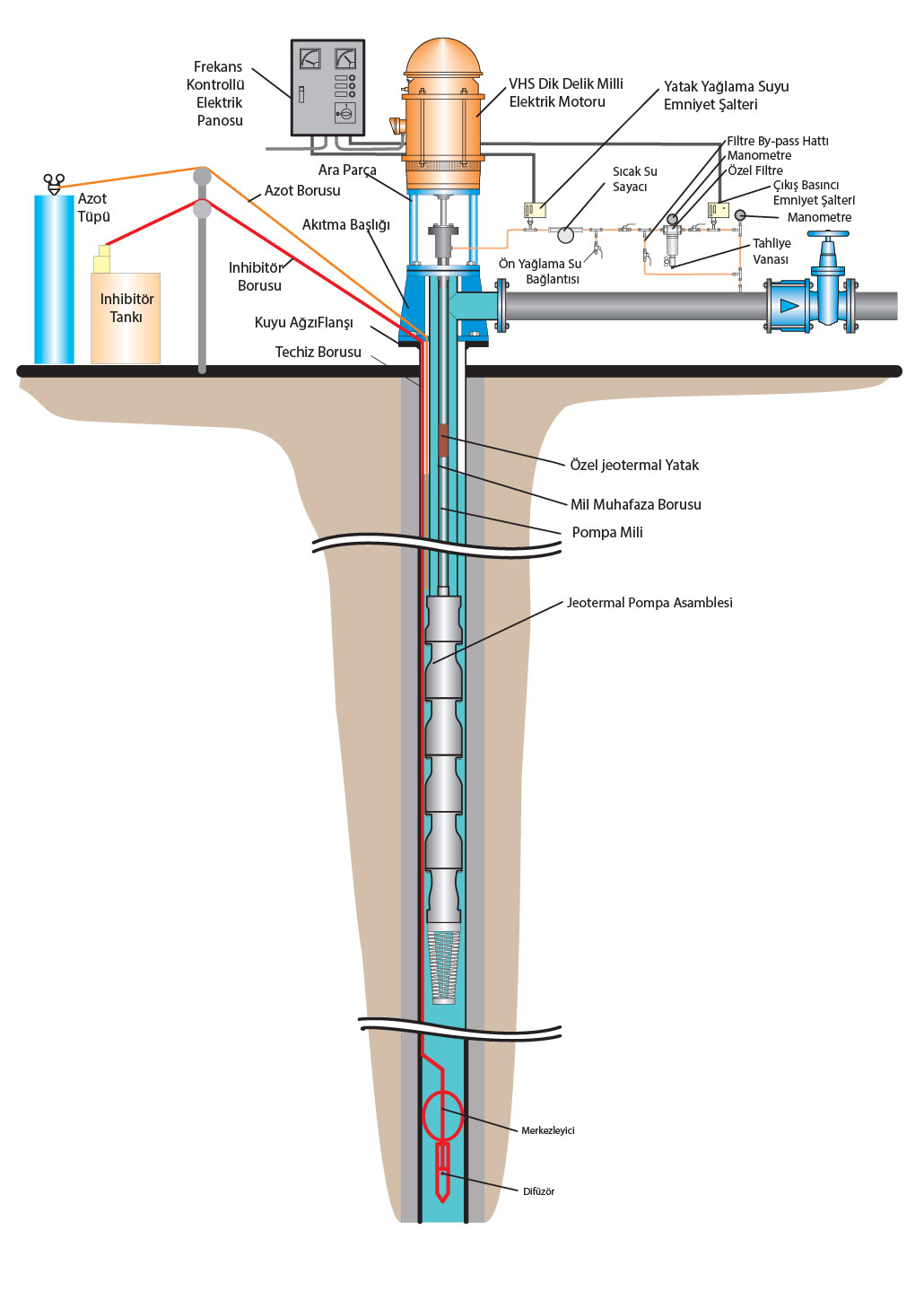

In Vansan geothermal pumps, the shaft is enclosed in a shaft enclosing tube and the bearings are lubricated with water. The discharge head is placed on the ground and carries the column and pump assembly located at the lowest level. Column pipes are usually manufactured with screws or flanges. There is a bearing at each connection point of the shaft enclosing tube. There are shaft enclosing tube retainer at the connection of the column pipes. The pump assembly located at the lowest level is designed specially not to be adversely affected by the axial elongation differences.

Elongation differences at Geothermal Pumps

Main problem of down hole Pumps is elongation differences between column pipes and column shafts during start up, which should be taken care of during construction. In all wells there is a big water temperature difference between well bottom and well top.

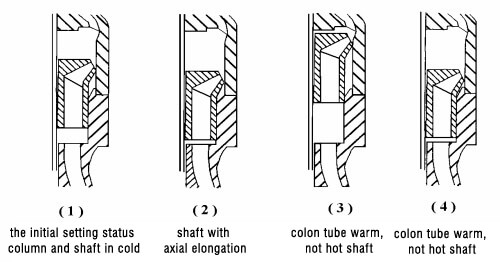

Vertical turbine pumps should be examined in two parts to understand elongation differences. First part is the stable parts like column pipes, enclosing tube and diffusers. The other one is the moving parts like shafts and impellers.

Before the pump is started position of impellers in pump bowls is indicated in (figure 1).When the pump is stared column shaft elongates under the down thrust forces (figure2). When hot geothermal fluid rises up and reaches the pump after a short time. Because of area of column pipe per unit mass is much greater than the column shaft, column pipe elongates more than schaft in a short time results, the pull up of impellers in bowls ( figure3). After the column shaft heats up and shaft and pipe temperatures are equal, impeller resumes its original position in bowls (figure4).

Geothermal Discharge Head Assembly

Discharge head must be rigid enough to carry the weight of the complete pump and motor and axial thrust. Bottom flange must seal the column pipet o allow pressurization of column to prevent the boiling of geothermal fluid in the well and should not transmit the heat from the fluid to the motor. Also carry the axial thrust bearing system and column pipe streching systems. Discharge piping should not transmit any torque to the discharge head.

Inhibitor piping and water level measuring system

There are two small pipes running alongside the column pipe in the well. One is for inhibitör injection and the other for dynamic water level measurement. Injection piping must be long enough to prevent calcification approximately 50m. lower than phase separation level. Dynamic water level measurement system is also used for annulus pressurizing. Both piping may be combined by installing a header system at the well head.

It is important not to allow two-phase flow in the column pipe as a result of the decrease of the pressure of the geothermal fluid at the pump outlet. For this reason, the pressure at the outlet of the flushing head must not be lower than an outlet pressure to be calculated depending on the temperature of the fluid and the quantity of the gas. This pressure is not a loss in the heat exchanger, as it can be used in the re-injection.

Pump Assembly

Pump assembly consists of suction case, intermediate bowls and impellers and discharge head. Pumps are designed to deliver the required capacity at the required head. Beyond of this basic requirement another important requirement is to minimize the life cyles of geothermal pump. To achieve this important requirement pump must be designed and selected to work efficiently over the whole range of frequency controlled operating conditions.

Vertical turbines can also be used with or without coloumn pipes instead of horizontal multi stage centrifugal pumps.