VSM ENCAPSULATED SUBMERSIBLE MOTORS (ENMOT)

FEATURES

- Motor casing and shaft made of AISI304L Stainless Steel

- Upper and lower bearing body is made of GG25

- Heavy duty thrust bearing

- Standard mechanical sealing ( SiC-SiC)

- Sand slinger protection

- Pressure equalizing diaphragm

- Insulation Class F, Protection IP68

- Removable lead cable (4m)

- Starting method D.O.L. and star/delta

OPERATING LIMITS

- Max. voltage fluctuation: ±10%

- Max. water temperature: 35 ºC with at least 0.16m/s of water flow speed

- Max. motor startings per hour 20/h – D.O.L.

- Max. immersion depth: 350 m

- Standard mounting position: vertical and horizontal

Extremely simple and very practical power cable connection to the motor body.

Heavy duty bearings provides the option to revolve both sides, has the capacity to carry high thrust load.

Although mechanical seal is optionally used by other companies, it is always used by Vansan as a standard,to prevent sand and other particles to get in motors to provide long bearing life.

Chrome-plated and precisely machined bearing collets which are located in the radial bearings operating area, have great importance for bearing the rotor.

When the pressure drops, it filtrates the water inside well and gets it inside the motor by the help of this checkvalve to balance the pressure inside. That’s why pressure differences inside motor never causes membrane under motor to blow up.

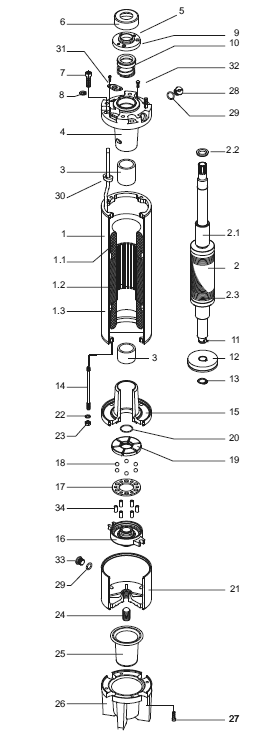

GALLERY

| No | Part Name | Material |

|---|---|---|

| 1 | Stator | – |

| 1.1 | Winding wire | PVC – P.P |

| 1.2 | Stator package | Magnetic Seal |

| 1.3 | Stator shell | AISI 304 |

| 2 | Rotor | – |

| 2.1 | Shaft sleeve | St 37 (Coated CrNi) |

| 2.2 | Balance ring | St 37 |

| 2.3 | Copper ring | Cu |

| 3 | Radial bearing | Carbon |

| 4 | Upper bearing body | GG20-22 |

| 5 | Bushing | Bronze |

| 6 | Slinger (sand guard | NBR_EPDM |

| 7 | Hexagon socket cap screws | Inox |

| 8 | Copper ring | Cu |

| 9 | Cover seal | AISI 420 |

| 10 | Mechanical seal | Seramic Carbon |

| 11 | Axial thrust bearing key | AISI 420 |

| 12 | Axial thrust bearing | Carbon With Antimony |

| 13 | Retaining ring | St 37 |

| 14 | Tie rod | Inox |

| 15 | Lower bearing body | GG20-22 |

| 16 | Thrust bearing support | GG20-22 |

| 17 | Ball holder | St 37 (Coated Cr+3) |

| 18 | Thrust bearing ball | Inox |

| 19 | Tilting pads | AISI 420 |

| 20 | O-ring | NBR 70 |

| 21 | Thrust bearing body | GG20 |

| 22 | Copper ring | Cu |

| 23 | Nut | Inox |

| 24 | Screw (thrust bearing base) | Inox |

| 25 | Membrane | NBR-EPDM |

| 26 | Membrane body | GG22 |

| 27 | Hexagon socket cap screws | Inox |

| 28 | Check-valve | Bronz |

| 29 | O-ring | NBR 70 |

| 30 | Cable seal | NBR |

| 31 | Seal cover | AISI 304 |

| 32 | Nut | Inox |

| 33 | Plush (r 3/8″) | Bronz |

| 34 | Ball holder pins | Inox |

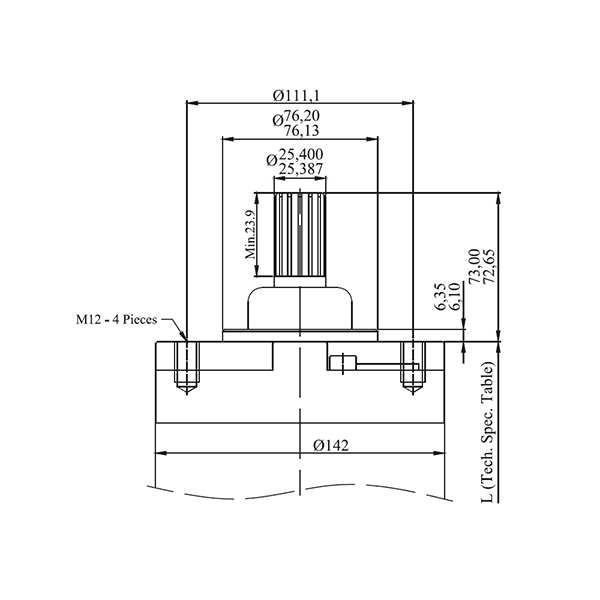

General Features

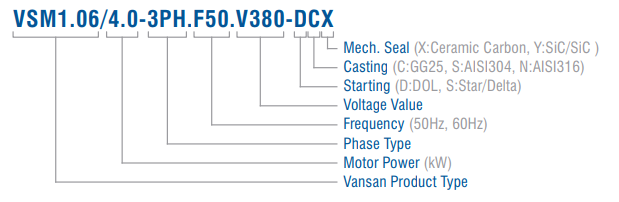

Product Code System